Advanced Components

// Performance Advantage

Advanced Components

Complex Geometry

- We thrive on the challenge of machining complex geometric parts.

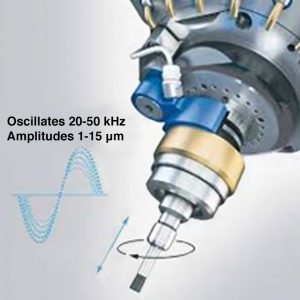

- Our 5‑axis DMG‑MORI DMU50 Ultrasonic milling centre equipped with

a robot pallet changer allows us to tackle any advanced shape

cost effectively. - Additionally, our 4‑axis DMG‑MORI NLX1500SY lathe with live tooling can produce high quality complicated parts.

Hard and Brittle Materials

- The ultrasonic feature on the DMG-MORI DMU50 pulses the shaft between 20,000 – 50,000 Hz with small amplitudes between 1-15 μm while machining the part.

- High performance materials which are normally difficult to machine can cost-effectively be processed with the highest of quality.

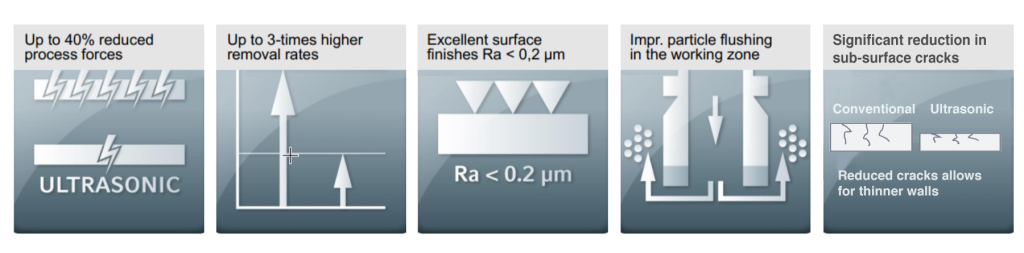

- The unique features of the Ultrasonic technology are (depending

on material):- Up to 40% reduction in machining forces and tool wear.

- Up to 3‑times higher material removal rates.

- Excellent surface finish. Possible to obtain Ra < 0.2 μm.

- Improved particle flushing due to smaller chip sizes that improve cooling, accuracy and surface finish.

- Significant reduction in sub‑surface cracks improving quality and making thinner walled parts feasible.

- Examples of Hard and Brittle materials that can be machined are:

| Hard | Hard and Brittle |

| Super alloys | CMC |

| Tungsten | HIPed Zirconium |

| Carbide | Zerodur |

| Titanium | Quartz glass |

| René 95 | Sapphire |

- We can of course machine conventional materials such as:

- Aluminium, Steel, Stainless Steel, Brass

- Acetal (Delrin), PPS (Ryton), PTFE (Teflon), PVC, Nylon